This post contains everything you need to know about how to reduce food waste in your restaurant business.

Why you should reduce food waste.

How to reduce food waste from your kitchen.

And even how to stop your customers from wasting your food.

Let’s get started then, with the why.

Why you should reduce food waste

Food waste costs UK restaurants £682 million each year.

In the US, the scale of the problem is far worse, costing restaurants $25.1 billion annually. Restaurant owners and managers are acutely aware of the problem, with 52% of restaurant professionals naming high operating and food costs as a top challenge.

This waste takes a huge bite out of many restaurant’s profits, and it is also incredibly damaging to the planet.

Food waste as a whole is a huge waste of basic resources that could be used for nature, or for feeding hungry people. Take land as an example: the land used to grow food that is subsequently wasted makes up an area 58 times the size of the UK, or almost 3 times the size of the Amazon Rainforest.

The land that is used to grow food that is subsequently wasted makes up area 58 times the size of the UK

Food waste is also warming the planet: if food waste was a nation, it would rank as the third largest national emitter of greenhouse gases, after China and the US.

But, food waste also ranks among the easiest and biggest environmental opportunities available to us, probably because it’s a total win-win: not many solutions to climate change immediately save us money.

On average, businesses save 7 times what they invest in reducing their food waste! This means that pretty much any food waste reduction strategy you try will be a financial success.

We’ve put together a comprehensive list of all the things you can do to reduce your waste and save money on food. Find an approach that works for you, implement it, and you and the planet will soon be reaping the benefits.

This post focuses on kitchen waste, but we’ve recently posted blogs on plate waste and forecasting techniques for a complete view of everything you can do to reduce COGS.

How to measure your restaurant waste

What gets measured, gets managed, and the first step to a successful kitchen waste reduction plan should be to measure how much you are wasting, the cost of that waste, and what the sources of the waste are. If you measure your waste for a trial period as short as a week, you will get a pretty accurate idea of the current state of your food waste.

The simplest way to measure your food waste is by using separate bins / trash cans for different types of waste:

- Bin 1: Preparation waste – the waste generated while prepping food e.g. broccoli stems.

- Bin 2: Spoilage – Food that has gone off while sitting in your fridge or other storage.

- Bin 3: Plate waste – Served food that customers didn’t eat.

Weigh each bin at the end of each day, or even better at the end of each service. If you don’t currently own a set of bin / industrial scales and don’t want to spend the money for a short-term project – a good set of parcel scales can be strong enough to do the job.

From your week’s data, calculate how much waste you are producing each year. Then multiply this by the cost per tonne; the average figure in the UK is £3,500.

You will then know roughly how much wasting food is costing your business each year. It’s likely to be a surprisingly large number, but don’t be alarmed! Lot’s of practical advice for making improvements incoming…

Tech alternative: If you are running a large operation and really want to get to grips on your food waste, Winnow’s smart bins have an inbuilt scale and identify food items as they are thrown in, using AI.

How to get employee buy-in

Any successful food waste reduction program will rely on committed staff members. Without the buy-in of your employees, it will be an uphill struggle. Here are some tips on how to get them on board.

- Make sure there is no fear attached to tracking waste. The carrot is definitely better than the stick here, as waste can easily be covered up by popping it in the wrong bin and thereby ruining the accuracy of your waste tracking. Make sure that an open environment is created, where wasted food is not viewed as a result of poor performance on the part of staff. Communicate this clearly before you begin measuring waste.

- Hear and implement suggestions of employees. If staff feel that they are heard, they will take ownership of the project themselves, ensuring consistency and accuracy. Kicking off the project with a quick brainstorming meeting including all staff is a good approach.

- Go armed with data. It’s a good idea to complete your initial measurements before scheduling your kick-off brainstorming meeting. Staff will take the project much more seriously if they understand the huge losses associated with waste. They will also come up with better ideas if they can see where the waste is coming from.

- Make the ingredients sacred. Most people who work in kitchens have a huge love and respect for food – they all agree that good ingredients are sacred, and shouldn’t be wasted. Without being too preachy, stress this point, emphasizing the farms, farmers, animals, land and natural resources that have produced the food. Also emphasize the environmental issues involved with food waste. Stay tuned to this blog for our hard-hitting upcoming post on the environmental impact of food waste – print it out and pass it around the kitchen!

- Give them what they need. Make sure your staff have suitable equipment that will make the task of waste reduction as easy as possible. If staff see you investing cash and time in the project, they will recognise the importance of it.

How to set reasonable targets for waste reduction

Setting realistic targets for waste reduction will motivate your team and give everyone a great sense of satisfaction when you totally smash through them.

In Champions123’s research, which involved 114 restaurant sites across 12 countries all undertaking a waste-reduction program, the average result after 12 months was a 26 percent reduction of food waste by weight. After three years, the average result was a 58 per cent reduction by weight.

The best-performing sites achieved a reduction of over 95% of food waste weight. This is an inspiring achievement that shows what is possible, but to avoid disappointment, it may be best to shoot for the average.

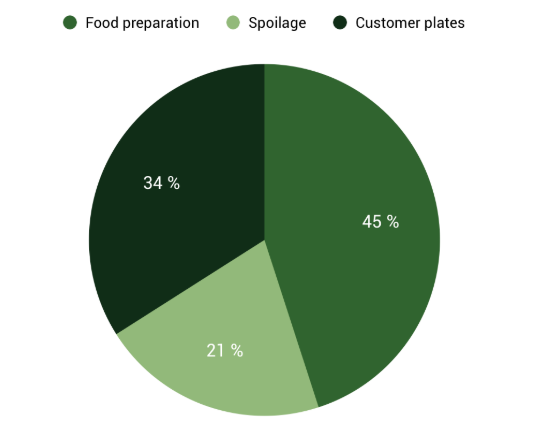

Once you have measured your major sources of waste, compare your numbers to the average proportions – see the pie chart below. This will show you where you are falling short compared to the rest of the industry. Set more aggressive targets for the areas where you are doing badly, and more relaxed ones where you already do well.

Where restaurant food waste comes from. Data from wrap.org

Where restaurant food waste comes from. Data from wrap.org

Part 1: How to reduce spoilage waste

Of the three major types of waste shown in the chart above, spoilage waste may be the smallest but is also the easiest to prevent, and in many ways, the most inexcusable. A careful commercial kitchen will have very little spoilage waste, and a very careful kitchen will eliminate it altogether. To state the blindingly obvious, letting expensive ingredients rot makes little business sense!

1. Avoid over-stocking ingredients

Forecast better

What are your expected sales on Wednesday? If the answer is “the same as last Wednesday”, chances are you’re going to miss the mark.

In a highly competitive industry with tight margins such as restaurants / F&B, accurate demand forecasts are often the difference between a business that is profit-making and one that’s destined to fail. The sales forecast determines not only your stocking levels for ingredients but also your labour schedule – in other words, all of your variable costs.

As forecasting specialists, we are constantly surprised by how primitive our clients’ and prospects’ forecasting methods are before they start using Tenzo’s automated AI forecasts. It’s very rare that there is a process defined. Konrad Edwards, one of the data scientists who built our restaurant forecasting software , likes to say that the general approach taken by most of the industry is to “hire a psychic”.

If you don’t currently have the budget for Tenzo’s automated forecasts (it’s great value!), that’s fine, there are probably a few things you can do to improve the accuracy of your current sales estimates, though it might not be easy.

Here’s some basic advice from Jiaxin Chen, one of our other data scientists at Tenzo, who focuses on creating ever more accurate sales forecasts.

- Consider corresponding past sales – Look at sales on the same day for the last 4 weeks. The most basic approach is then to average these numbers to get a four-week-moving-average, a decent forecast base. Even better, create a “weighted average” which favours the more recent sales figures.

- There is no forecast for all seasons – Seasonality is generally the most powerful predictor of sales volume. When it’s necessary, consider different seasons of the year separately. For example, identify when your summer busy season tends to begin, and adjust your 4-week-rolling-average base according to how big of a jump in sales you usually see in the spring to summer transition. If you skip this step, you could be caught out badly when the seasons change.

- Take into account events – If there is a large local event or national holiday on the day you are trying to forecast, such as Mother’s Day, or Valentine’s Day, your forecast needs to be adjusted. Look at the percentage jump you saw on the day of the event last year. If it’s a one-off event, your best bet might be to have a guess but take some time to consider the likely impact carefully. Also, when you are generating a four-week-moving-average, make sure you never include any days when such events occurred.

- Understand your key factors – This is the bit that the above mentioned “psychics” do based on gut-instinct. Consider what the key factors are that affect your sales – a restaurant on the seafront in a holiday town will have wildly different key factors than a QSR in the City of London. Key factors can include seasons, weather, events, or week-day, and each restaurant will have a unique mix. We recommend trying a data-led approach, figuring out from your past sales how much these factors affect your business and creating some simple guidelines to use when creating forecasts. You might need a bit of data analysis skill here.

Jiaxin Chen – Tenzo forecasting scientist.

Jiaxin Chen – Tenzo forecasting scientist.

Need more practical advice on forecasting better? We will post a deep-dive on forecasting techniques in the next few weeks, so subscribe to be alerted!

Push sales of items you are overstocked on

Pushing sales of overstocked food items is a technique as old as time, but given the environmental imperative to reduce waste, it’s now more appropriate than ever. Here are the basic approaches:

- Get floor staff to recommend dishes containing overstocked items – Diners often ask waiters to recommend dishes. Most waiters simply recommend their personal favourite because they get little direction from the kitchen on which dishes need to be pushed. Set up a meeting before each service that ensures floor staff are always informed when a dish needs pushing, then show them how to push that particular dish. Even better, set up a competition and reward the staff member who sells the most – Tenzo users can do this easily by using the “% attachment by product item metric in the “employees” module. For a master-class in pushing specific menu items, watch this.

- Specials – I used to work in a sustainable fish restaurant where the head chef was a master at using his specials board to drive great COGS. When vendor prices were low for skate wing, for example, he would very quickly create a delicious new skate wing dish for the specials board, even if we had skate wing on the menu already. This drove more sales of the ingredient and allowed us to shift more of this high-margin item. He also used the specials board in a similar way to shift overstocked or slow-moving items, keeping waste very low. One important principle to follow when doing this is to make sure that the dish you put on the specials board is sufficiently different from the dish that you already have on the menu which contains the same principle ingredient – without doing this, the special will cannibalise your menu item and you won’t increase sales overall by much.

- Staff meals – every restaurant should be using staff meals as a lever to reduce waste. If a meal is made in error – managers should be on the lookout for a staff member who is due for a meal break who is willing to eat it. If an item is heavily overstocked, make that the staff meal for the day. Far too many restaurants use an inflexible (or overly flexible) staff meals policy that doesn’t aim to reduce waste. Note – restaurant staff often view enjoying staff meals as an important perk of working in the industry – ensure your managers don’t force staff to eat dishes they don’t enjoy, or you risk causing a major upset.

2. Be strict with vendors

Resist being sold more than you need

Some vendors will sometimes deliver more than was ordered, then charge you for it. Make sure that all deliveries are checked to make sure that they conform strictly to the original order. Reject anything additional.

Vendors also tend to use the hard-sell on items that they have overstocked, with special offers and discounts for volume. These can be great items to build high-margin specials on, of course, but caution should also be taken to ensure you don’t end up with more than you can sell. Look at the popularity of similar specials you have tried in the past before putting in a big order. Note: this is quick and easy with Tenzo, meaning you can check your past specials while the vendor waits.

Reject food likely to spoil quickly

Reject anything with visible spoilage on delivery – it will soon be on the way to the bin either way, and better the vendor’s bin than yours. Note: Blemishes and discolourations on fruit and veg don’t necessarily mean that the produce is on its way out. Make sure that staff inspecting deliveries know the difference between actual spoilage and mere ugliness – absurd retail standards for aesthetic produce are a major cause of food waste. You might even be able to negotiate a knock-down price for the “ugly” produce.

Reject food stored at the wrong temperature – Another thing to look out for is food stored at the wrong temperature. Meat, poultry, dairy, seafood, eggs, and anything cooked or ready to eat should be delivered below 5 degrees celsius. Any temperature higher than this is the “danger zone” where bacteria will start growing, increasing the rate of spoilage and the risk of food poisoning. Consider this: bacteria populations double every six days when kept at 1℃ (34℉), and double every six minutes at 22℃ (72℉)!

Get deliveries during slow or off hours – Often the reason for badly checked deliveries, or slow refrigeration (see section 4) is that deliveries are made when staff are busy with prep or service. Arrange to have deliveries made when your employees have time to deal with them quickly and correctly. If this isn’t possible, schedule an extra employee for days when you expect a lot of deliveries. You will save a lot more money in prevented spoilage and also make sure your ingredients are always fresh – customers will notice the difference.

3. Avoid over-prepping

Over-prepping is a common scourge of unprofitable kitchens and it often comes down to simple culture – kitchen staff, like overzealous boy scouts, hold the mistaken view that more preparation is always good. When it comes to food, this is not the case. Over-preparation will lead to wasted ingredients and in many cases having pre-prepped ingredients sitting around for hours impacts the quality of dishes.

A simple culture-shift is relatively easy to achieve, and will naturally emerge out of your company-wide waste-busting project. However, creating the optimal prep-sheet is an art-form, balancing risk of waste against the risk of running out of dishes.

Forecast better

Creating more accurate forecasts, as detailed in section one, will help you to adjust your prep-sheets in line with expected sales. See that section for more information on how to do this.

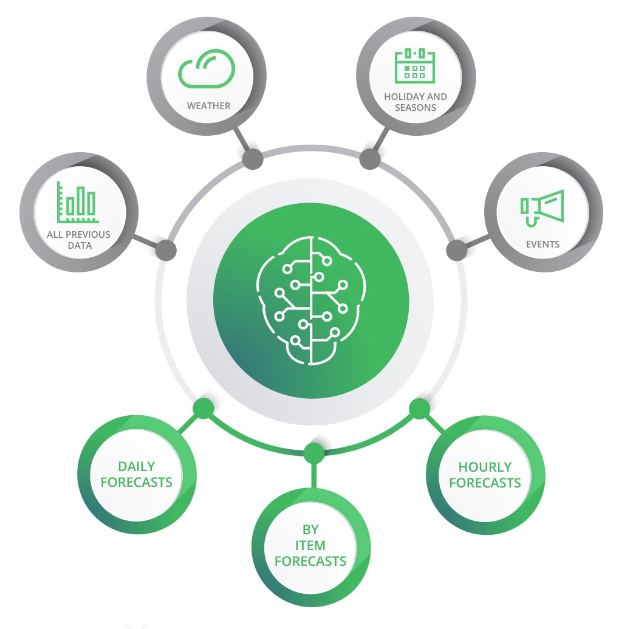

However, there is a lot of variation in which dishes sell that depends on weather, day of the week, season, and local events. Taking all this into account and adjusting preps sheets according can be roughly eyeballed by a very experienced chef, but simply cannot be done accurately – there are just too many factors to take into account!

Accurate item-level forecasts are somewhat of a holy grail for restaurants – optimising both ingredient use and kitchen staff time, while minimising the likelihood of disappointing customers by running out of dishes.

Tenzo uses machine learning to create extremely accurate menu-item level forecasts and automate the creation of prep-sheets for every service. The AI allows us to take into account far more factors than a human planner could. For more information on how these forecasts work, get in touch!

Tenzo’s AI forecasting take into account all relevant information, including weather forecasts and local events, to automatically create item-level forecasts.

Tenzo’s AI forecasting take into account all relevant information, including weather forecasts and local events, to automatically create item-level forecasts.

Be prepared to run out

Running out of dishes is obviously not a good thing. Customers can be fairly disappointed if their favoured dish is not available. However, balancing this risk with the risk of over-prepping and wasting ingredients means you have to accept an occasional let-down customer.

Having said that, there are some dishes you should aim never to run out of. Any dish that is a house speciality, is extremely popular, or that you are known for, should always be available. Also, there should always be options for special diets available – if you have a single vegetarian or vegan item on your menu, running out is a big deal.

Delist or alter dishes which drive waste

Tracking your waste will help you to identify those dishes which drive your over-prepping waste. Once you’ve identified these problem dishes, find a solution for each.

- Unpopular dishes that drive waste should probably be removed from the menu.

- Is it really necessary to prep for these dishes? Can they be made to order instead?

- If not, can the recipe be changed to remove the need for prepping?

- Should the ingredients be prepped in vacuum bags, so that they can be safely stored in the fridge for several days?

There are many possible solutions. Treat each dish as a separate puzzle, and you will quickly find solutions.

If you still over-prep, donate or sell online

Lot’s of amazing tech startups have been founded in recent years to combat the waste problem in commercial kitchens.

Olio, Food Rescue, and Food Rescue US, are all apps that connect food businesses with non-profits that can redistribute surplus food. They will arrange for pick up your food and deliver it to those in need in your community.

If you want to make a bit of money out of your daily surpluses, Too Good To Go, and Karma are both apps that allow budget-conscious consumers to browse nearby surplus food available for pick-up at the end of each day.

4. Improve storage methods

One of the easiest ways you can reduce waste is by putting in place simple checks and processes to make sure that food is stored correctly. It’s surprising how many restaurant kitchens do not strictly adhere to best practice.

Ensure food is stored at the correct temperature – Many fridges and freezers are not set cold enough. Here is a reminder of the most important guidelines for food storage:

| Fresh meats, produce, and dairy. | 1 to 2℃ (34 to 36℉) |

| Fresh fish and seafood. | -1 to 1℃ (30 to 34℉) |

| Freezers |

-21 to -18℃ (-5.8 to 0℉) |

Other things to do to ensure correct temperatures are to set up a regular maintenance program for all your refrigerators, and to fit curtains on your walk-ins. Doing a monthly clean of your filters is the best way to ensure good fridge performance and reduce chances of break-down.

Refrigerate deliveries as quickly as possible – A head of lettuce will lose one day of shelf life for every hour that it is not refrigerated. As mentioned in section 2, make sure that staff are trained and available to put away deliveries as soon as they come in, and schedule deliveries for slow or down time.

Use tech to increase shelf-life – There are various cheap technologies available that will dramatically prolong freshness.

- Bluapple, for example is a (fittingly named) blue, apple-shaped ball which absorbs ethylene gas – the signal that prompts fruit and veg to rapidly ripen. Popping one in the fridge can make produce last up to three times longer.

- Vacuum sealing is another great waste-busting technology. Nowadays cheap, these suckers can pack your ingredients in plastic and remove all the air. You can then cook them in a vacuum, pasteurising them, meaning they will last much longer in the fridge. It’s a great method which allows you to batch-prep meats and veggies on the day you receive them, and store them safely throughout the week.

Organisation – Keeping storage areas neat and tidy and storing similar items in the same section not only saves your staff time and headaches, but also helps to cut down on waste. Great organisation will cut down errors in your stocktake, and also prevent items from being put back in the wrong place to be “lost” and subsequently spoiled.

For example, having one fridge to receive all goods and one for all prepped food is a good health and safety practice but also helps with organisation.

Involve various kitchen staff in the reorganisation of your kitchen storage – this will ensure that the optimisation helps everyone, that they remember where the changes were made, and that they will be fully on board with the changes.

5. Use stock rotation best-practice

The FIFO rule – A first-in first out (FIFO) policy is the gold standard for restaurant storage – it’s hard to find a professional kitchen these days that doesn’t use it. However, it’s more rare to find a kitchen that successfully adheres to the FIFO rule 100% of the time. Bad labels, rushed staff, and disorganised fridges and freezers are the common causes.

Labelling. Don’t be tempted to save money on labels and use cheap masking tape instead. Investing in proper sticky labels that are fit for their specific purpose, like the selection available from dot it, is a no-brainer. Masking tape = chaos.

Left to right – Keep your oldest perishable ingredients on the right-hand-side of your fridges and freezers. When new food of the same type is added, put it on the left. Make sure you keep moving the oldest stuff to the right, and stick to the rule of adding newer food to the left, and you will cut down on waste, as well as saving time during service. Ensuring staff stick to this policy is the hard part – implement proper training, regular checks, and put signs on fridge and freezer doors to remind staff of the policy.

Keep great inventory records. Doing an accurate and thorough stock-take at the end of each day is of course essential. Make sure to build in a tidying process, so that the member of staff doing the stock-take ensure that the fridges are set up to make FIFO easy during the next service. Use a modern inventory system to keep your inventory. Tenzo recommends Marketman, Kitchen Cut, Caternet, and Simple-order – these are all great inventory software options – the benefits go far beyond more efficient stock-takes.

6. Reduce your menu size

Perhaps the most powerful thing you can do to reduce food waste in your restaurant is to reduce the number of dishes on your menu.

Having fewer items to order, store, prep, and serve, helps with almost every other point covered in this guide:

- It’s easier to identify sources of waste with fewer dishes.

- It is easier to forecast item demand for fewer items bought in higher quantity.

- It’s easier to conscientiously store and adhere to good stock rotation practices with fewer items

- It’s easier to ensure good prep training with fewer ingredients.

- It’s easier to track & compare vendor prices, and negotiate good deals with fewer ingredients.

Aside from preventing food waste, there are many other advantages to a smaller menu, including helping to define your concept, having to deal with fewer suppliers, and making customisation of dishes easier.

Smaller menus are also preferred by customers. Research says that 10 mains is the optimum number for a modern menu. Any more, and diners will be overwhelmed by the amount of choice. But be careful of going too spartan – many diners still appreciate having a variety of choices.

Part 2: How to reduce restaurant preparation waste

According to the Wrap.org research cited in the introduction to this guide (see the pie chart), preparation waste accounts for a huge 45% of restaurant food waste. That’s more than twice the waste that generally comes from spoilage, so getting this part right is absolutely crucial to successful food cost and waste reductions.

Generally, preventing preparation waste comes down to three simple, but hard to master, factors:

- Training chefs to reduce waste. A well-trained chef knows how to prep every ingredient with minimal waste, and how to repurpose trimmings. However, you can’t expect chefs to have perfected this art before they start working for you, so a great training process for new chefs, and regular prepping masterclasses will be required.

- Ensuring chefs remain conscientious about reducing waste. If the importance of reducing waste is not regularly communicated, kitchen staff can get lax. Keeping standards high requires great processes and communication.

- Use your scraps. Many food “scraps” from preparation are perfectly edible, nutritious foods. Converting th